Into the woods by 7:30 AM. It was cold overnight, 10, but we can work through the cold. Expected an easy day. 160 gallons with the R/O should take 3 hours. With startup and shutdown time we should be done by Noon or earlier.

The R/O was still running the wash cycle when we arrived in the woods at 7:30 AM. Temperature was only 104. Something was off. It should have shutdown automatically after reaching 113. That should have taken 6 hours maybe. Turned off the R/O. Not sure of the impact of an incomplete wash cycle.

Started troubleshooting. Found a cracked valve on the R/O wash tank. It wasn’t leaking, but if it compromised the seal it could have pulled in air disrupting and cooling the circulating water. We made arrangements to get a new valve. Another concern was the quick release on the new feed pump may not be sealing tight enough. It’s not leaking, but if the seal is compromised, it could pull in air and disrupt the pump. A symptom we noticed is the feed pump not reaching and holding 25 PSI. It normally takes under 5 seconds when water or sap is present. Found enough fittings to replace the quick release and made a new line connecting to the feed pump.

Installed the new valve and reconnected all lines to the pump, then tried to prime the pump. Water from the storage tank wasn’t flowing to prime the pump. Suspected a frozen line leading from the water storage tank to the pump. Found a wire to use as a snake to probe the line. Encountered ice where the line enters the building. The heat tape didn’t extend through the wall and the room heater didn’t warm though the wall. Used the heat gun to thaw. Reconnected the lines. The pump primed so we could pump water through the R/O. Things were looking up.

Configured the R/O to concentrate sap. Opened the sap feed value. The feed pump couldn’t reach 25 PSI. Suspected another frozen line. A few minutes with the heat gun on the tank and we heard the gurgles of sap moving in the line. But the feed pump still wouldn’t reach and hold 25 PSI. Took off the line from the tank to R/O. A lot of work removing it to find no ice. The line connecting to the tank must have had the ice. Back with the heat gun. Thawed it again. Reconnected everything. The feed pump got sap and held 25 PSI. Started concentrating with the high pressure pump. All my preparation with heating tapes and tank heater yesterday didn’t help because we didn’t account for the place the line enters the building. It was Noon. Expected to be done by this time.

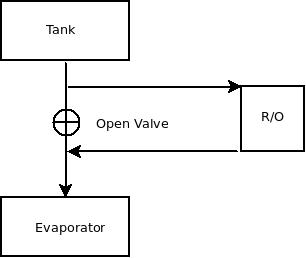

The challenges weren’t over. Expected the R/O to finish by 1:30 PM. It didn’t. The Brix kept increasing. By the end of the day it was reaching 12 Brix. And the temperature increased to over 70. This isn’t normal. We speculate we were feeding the sap through twice. The valve from the storage tank to the evaporator was open. We opened it while troubleshooting the frozen pipe: if sap could flow from the tank to the evaporator, it would also flow to the R/O because the R/O feed line branches off up-line from the evaporator. At shutdown we noticed the valve to the evaporate was still open. That could explain the higher Brix and temperatures because with that valve open, sap from the storage tank and concentrate tank can mix allowing sap through the R/O twice.

A wash cycle is running now. Hoping it reaches and shuts off at 113 and doesn’t run all night. We’ll see in the morning.

10 overnight. Snow flurries gave dusting of snow. High of 27. Everything stayed frozen.

The day cooking

11:00 AM -5 PSI

12:00 PM R/O start

12:00 PM -5 PSI

1:10 PM batch

2:00 PM Stopped R/O

2:20 PM batch

3:15 PM done

Back to the farmhouse by 3:30 PM.