The season is not over until all the cleanup is done. Into the woods by 10:00 AM for the final cleanup tasks. Floor washed. Tanks emptied and in the syrup building. Gas tank disconnected and back in the syrup building. Taped close gas burners and R/O hoses so no insects make homes in them during the off-season. Final task is unplugging the radio and taking down the clock. Back to the farmhouse by 1:30 PM.

A good season. Above average corp in quantity and quality. The R/O is such a game changer. It makes the season so much easier with much less time cooking and less wood used. We don’t even haul water any more. Very happy with the investment.

Wish we started earlier. There was a big run over February 18 & 19 that we missed because we weren’t tapped. Likely would have put us over 100 gallons of finished syrup for the season. It would have been a nice symmetry to have 100 gallons of syrup in season 100.

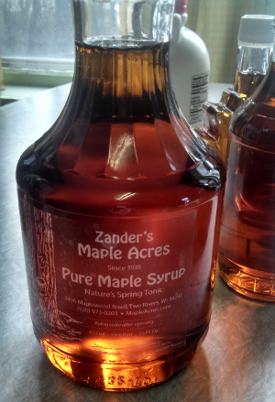

The new labels and branding is another big improvement. Real happy with how that turned out.

Thinking of entering syrup for judging at the meeting of the North American Maple Syrup Council in Lévis, Québec in October. Haven’t ever done that, but why not try.

Off-season improvements we’re considering:

- replace concrete floor

- new propane burners for finishing pan and in bottling kitchen to replace stove

- new sap hydrometer

- new fill spout on bottling pan to see if we can eliminate bubbles

- replace buckets with PVC sap sack holder and plastic sap sacks

- re-brick evaporator with firebrick after replacing metal sides

- finishing painting building and woodshed

- new base for the R/O water tank

- new transfer pump

All depends on how much money we want to spend.

We return in February 2018 to start the next 100 seasons.