The race was on to beat the ice. Boiled all night. Took shifts. Dad went in at 7:30 in the evening. Dean and Karl stayed until mid-night when Dad came back to complete the boiling. He finished be 7:30 am. There is still sap in the evaporator waiting to boil down to syrup. But the sap is out of the tanks so we won’t get ice blocks. Once in the evaporator we can always start a fire to melt the ice. It took about 20 hours to boil through the sap. And we bottled 21 quarts of syrup already. At 10:26 pm CST we officially completed the first gallon of syrup for the 2004 season. Dad reports the morning shift from mid-night to 7:30 am was very cold! As the tanks emptied, the firing slows down and generates less heat. And then all the steam and dripping water starts to freeze. We have an impressive collection of ice hanging from the windows.

The trees worked overtime. They must have dripped all night. Trees tapped at 4:00 in the afternoon were full by 10:00 the next morning. A cold front was moving through and the weather changing. It was getting much colder, into the 20s. So the race was on to collect the sap before it all froze in the buckets. We started collecting about 10:00 am and were pretty much done by noon. We collected 400 gallons of sap. Ice was already forming in the buckets so waiting was not an option. As the weather was still getting colder we were still faced with ice in the storage tanks. So we started the evaporator to boil down the sap. We will boil all night. Tomorrow is also forecast to be cold, in the 20s. If we don’t boil down the sap our storage tanks will be a block of ice. It will be a long night.

Its tappin time. About 320 taps out now. Its a lot of work using the hand auger to drill the holes in the trees. After about 50 your arm starts to get tired. Each tap gets a hole drilled about 1 inch deep, a spout lightly hammered in, a pail and a cover for the pail. We use a tractor to takes the buckets and covers into the woods. The rain about a week ago melted much of the snow in the woods making it much easier to get around. Aap was following in the trees today. After drilling a hole, the sap started running out. There was a steady drip, drip, drip into the pail. It was sunny and about 40 degrees, but the wind was cold. The weather forecast is for cold and snow tonight and tomorrow. We will finish the tapping but do not expect to collect any sap yet.

M – Maple Sugar Trees that Stand so Tall.

A – All Trees the Good Lord Gave Us All.

P – Pure Maple Syrup that People Love.

L – Labor of Love Making Maple Syrup.

E – Enjoying Nature’s Pure Maple Syrup.

S – Sweet Sap that Drips from Maple Trees in the Spring.

Y – Your Work to Drill Holes, Pound Spouts and Hang Buckets on Maple Trees.

R – Roaming from Tree-to-Tree Collecting Sweet Maple Sap.

U – Using Evaporators to Boil Out Water Making the Sap Sweeter, Darker and Thicker as it Becomes Maple Syrup.

P – Pouring on Pancakes, Waffles and Many Other Foods Making Them Taste sooo Delicious!

Used with permission. Copyright 1998 Verna D. Zander

A few taps are out. Testing the weather. They are dripping. That is to be expected as it is the second week of March. Its actually getting late for tapping. There are usually several runs of sap. An early run at the beginning of the season. And heavy run about 3 weeks in with shorter runs in-between. Of course it is not predictable. Sap is the food the maple tree needs to make leaves so it has to go up some time. Freezing nights and sunny days help it move. So that’s the weather we wait for.

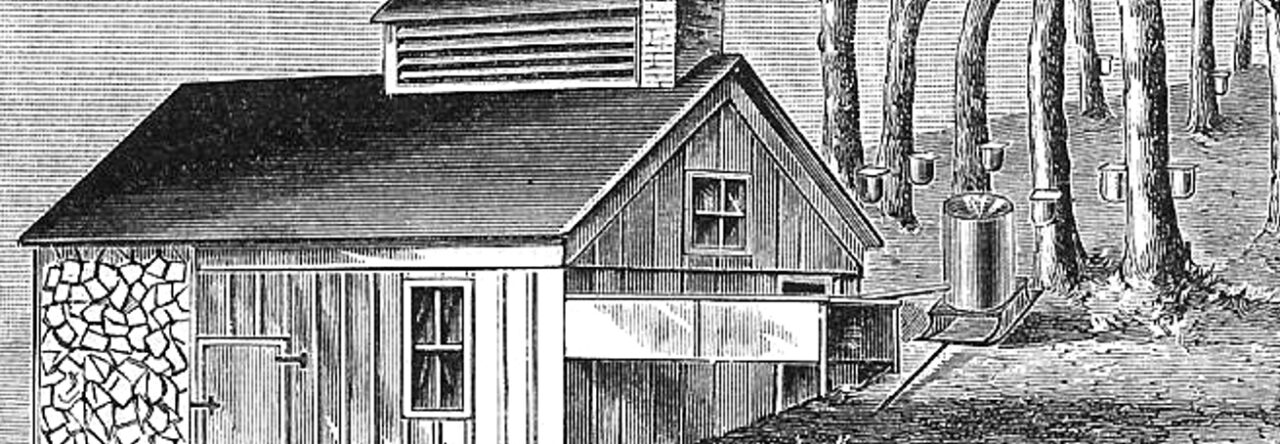

Getting organized for tapping this week. There is always great anticipation leading up to tapping. We know the whole season will be a lot of work, but we do it any way. Its a labor of love. As a small operation, we do everything manually. Tapping by hand drill. Buckets and spouts, no tubing. Collecting with 5 gallons pails. Boiling the sap over a wood fired evaporator. The wood shed holds about 12 cords of wood. All cut with chain saws and split by axe and sledge hammer. One cord of wood is 4 feet wide, 4 feet high and 8 feet long. Its a lot of work just cutting the wood. It takes about 10 hours to boil off 200 gallons of sap that results in 5 gallons of finished maple syrup. Yup…that a ratio of 40 gallons of sap to make one gallon of syrup. And finally all the bottling by hand. At an hourly rate, we would not earn much.

We purchased some new equipment this year. 200 stainless steel spouts to replace about half of our inventory of spouts. Our existing souts are old. Over 50 years old and maybe older. The new stainless steel spouts will be easy to keep clean. There is new technology in spouts called Micro Spouts used with tubing. They are very small and only use a small hole in the tree that heals within one year. But since we do not use tubing the Micro Spouts are not useful for us.

We also replaced the pan we use for bottling. This new pan is also stainless steel and replaces an old and well used bottling pan. And last year we got a stainless steel milk can to use for moving the syrup from evaporator to finishing pan to bottling pan. Stainless steel is so much easier to keep clean.

Like many agricultural products, Maple Syrup is dependent on the weather. Freezing nights and sunny days make the sap flow. The weather forecast for the next few days is stormy. 2″- 5″ of snow tonight and into tomorrow. Maybe by mid -week. In 2003 we tapped March 14-15 which was late.

Cloudy and rainy today. Northern Wisconsin got 6″ to 8″ of snow. But we only got rain. About 1″. It did help settle the snow in the woods. No tapping yet. Watching the weather carefully. Hoping the weather will break for tapping next week.

Welcome to MapleAcres. The 2004 Maple Syrup Season is just about here. We will attempt to chronicle the events of the season here. Please check back every day to see what’s happening in the sugarbush.